Sterilization Process (Super Cleaning Process)

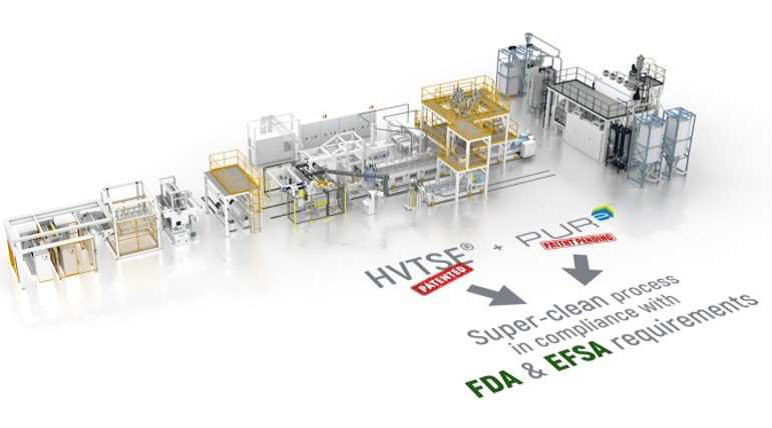

The purpose of the new process resulting from the use of the new Pure 15 equipment (Super Cleaning Process) is the gradual minimization of the use of virgin material up to 5% of the total product weight and its replacement with recycled material up to 95%, suitable for food contact. The sterilization process consists of the following three steps:

STEP 1

R-PET flakes are fed into the Pure 15 machine, while the unique traceability code is recorded.

STEP 2

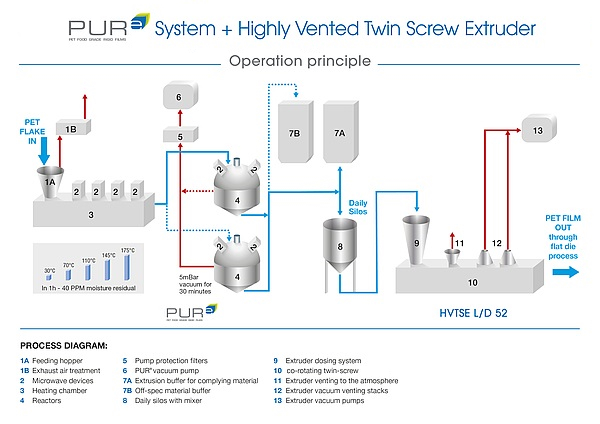

The flakes are preheated using microwave stations and sterilized in reactors batch by batch at high temperature and under vacuum process. Two reactors are alternately used, resulting in a semi-continuous process, where in the first reactor, the material is sterilized, while in the second reactor, material for processing is loaded, preparing for the next sterilization (Super Cleaning Process).

1. Hopper, 2. microwave devices, 3. heating chamber, 4. reactors, 5. vacuum pump, 6. ON- specification buffer for material complying with specified process parameters, 7. OUT specification buffer for material not complying with specified process parameters and subsequently removed, 8. co-rotating twin-screw extruder, 9. venting at atmospheric pressure, 10. venting under vacuum, 11. vacuum pump.

1. Hopper, 2. microwave devices, 3. heating chamber, 4. reactors, 5. vacuum pump, 6. ON- specification buffer for material complying with specified process parameters, 7. OUT specification buffer for material not complying with specified process parameters and subsequently removed, 8. co-rotating twin-screw extruder (Bandera), 9. venting at atmospheric pressure, 10. venting under vacuum, 11. vacuum pump.

STEP 3

The resulting sterilized flakes, now suitable for food contact, are conveyed through an air transport system to supply the production of multilayer reel in extrusion machines, in either the B or A layer.

The process is carried out with defined operating parameters [in accordance with Articles 9 and 20 of Regulation (EC) No 1935/2004], which parameters were provided to the EFSA and made available to the applicant, the Member States, and the European Commission.

The process is carried out with defined operating parameters [in accordance with Articles 9 and 20 of Regulation (EC) No 1935/2004], which parameters were provided to the EFSA and made available to the applicant, the Member States, and the European Commission.